Skid Design & Detailing Services

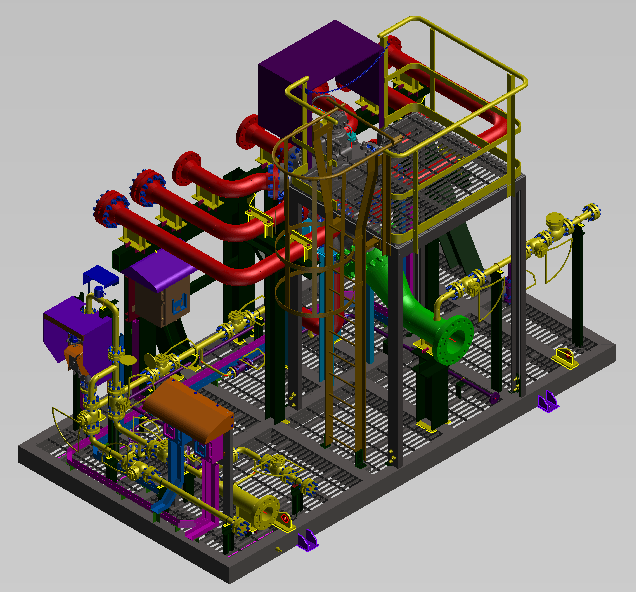

3d-labs specialized in cost effective structural skids designs services. A skid is a process system which contains a frame or structure containing pressure vessels, heat exchanger, pumps, valves, instrumentation, and so on.

3d-labs has wide experience in design of equipment and piping skids of a wide variety. Skid design will comply with international standards and customer specifications Ensure safe lifting, transportation and operation. Optimize skid costs, by reducing unnecessary costs Ensure sufficient stiffness (at key locations) to avoid vibration problems for components mounted on the skids.

We have rich experience of serving structural skids designs companies around global.

Below some of our skid projects completed:

Karish & Tawin FPSO project Haterboer- WAPL

Amine Refrigeration unit –

Carbon Bed Filtration Package

Particulate Filtration Package

Fuel Gas Skid – Techno Futura LLC

ROV Skid – Robstone FZC

Filter Skid – Robstone FZC

H2S Scrubber Skid – Robstone FZC

PRS Skid – Robstone FZC

Metering Skid – Robstone FZC

Odorizer Skid – Robstone FZCGas Scrubber Skid – Techno Futura LLC

Pressure Reduction and Metering System –Nigerian Gas Company

Platform & Staircase 1 for AIPL

Platform & Staircase 2 for AIPL

Pressure Safe Guarding Skid – Basrah Gas Company

Gas receiving Facility – MCSC

Pressure Reduction and Metering Skid – GASCO

Pressure Reducing and Instrument System

Skid – Saudi Electricity Corporation

Pressure reduction Skid – Sharjah electricity

and water Authority

High Pressure Flare Picot Skid – Qatar petroleum

H2S Scrubber & Odorizer skids – Techno Futura

MPFS Skid- PetroFac Electro chlorination Skid ABC&DEF

Kalf, SEPL

Skid load capacity

Precision Skid Design

TYPES OF SKID

CHEMICAL INJECTION SKID

Generally, the Oil and Gas Extraction process requires Injection for its application. Chemical injection systems typically consist of multiple chemical services with associated single or multi-compartment storage tanks or pressure vessels. In the Injection, Major factor is the Injection rate and Injection temperature. The purpose of injecting the chemicals into a system is to protect the mechanical integrity of the system from accelerated corrosion and prevent scale formation.

A modular process skid is a process system contained within a frame that allows the process system to be easily transported. Individual skids can contain complete process systems and multiple process skids can be combined to create larger process systems.

Hydraulic-surge package should be a complete surge analysis. Part of the results of such analysis is the determination of how much flow will need to be relieved and at what set pressure. These two design criteria will help select a properly sized surge-relief package which will reduce surge pressure to an acceptable level during unsteady state flow conditions.

Custody transfer in fluid measurement is defined as a metering point (location) where the fluid is being measured for sale from one party to another. During custody transfer, accuracy is of great importance to both the company delivering the material and the eventual recipient, when transferring a material

Truck Loading Skids to achieve reliable, accurate, and timely transfer operations over a wider range of products while preserving regulatory and safety compliance.

A pressure reduction station (ZV SKID) is used to drop a high supply pressure down to the pressure used by the downstream installation. They operate on liquids, vapors and gases.

download skid design book