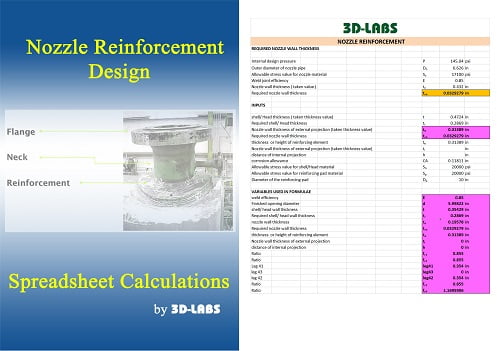

Nozzle Reinforcement Design

$4

All calculations are created by 3D-LABS, easy to execute any projects with our work procedure. after your payment, click download will be downloaded in spreadsheet format….

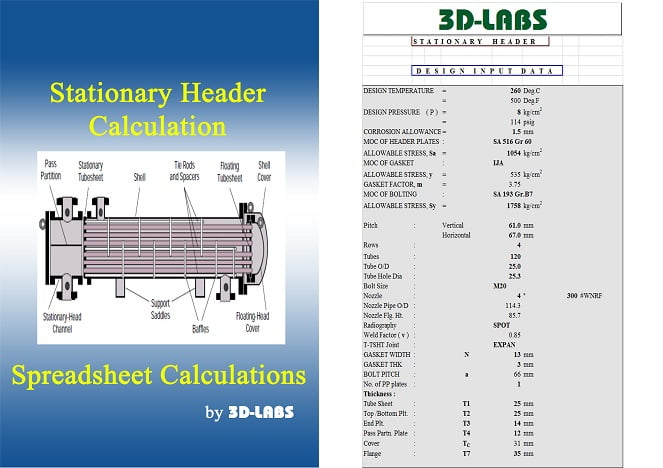

All pressure vessels must be furnished with nozzles and connections. The aim of nozzles is to interconnect the pressure vessel with the rest of the process. The most typical practice to join nozzles and pipelines is to use standard flanges; this ensures a perfect match at assembly and construction stages.

To attach a nozzle in a pressure vessel, it is necessary to make a hole in the shell or head body in question. When making this hole, an area of the vessel is being “taken away”, therefore stress paths are going to divert tangentially to the hole. Thus, we must “substitute” the removed area by adding reinforcement within the limits.

It should be noted that installing a nozzle in a pressure vessel involves a geometric discontinuity that must be taken into account in calculations. Consequently, every method that could be implemented to reduce existing stresses is welcome. One of the most commonly used methods consists in removing stress concentrators by means of rounding sharp edges.

This publication discusses about flanged nozzles that are more susceptible to fluid leakage than welded nozzles. A flanged nozzle consists of the three main elements: flange, neck and reinforcement.

Reviews

There are no reviews yet.