Description

All calculations are created by 3D-LABS, easy to execute any projects with our work procedure. after your payment, click download will be downloaded in spreadsheet format….

[contact-form-7 id="e2596aa" title="Spreadsheet"]

If you require any additional calculations or assistance, please do not hesitate to contact us. Our team is ready to provide the necessary support to meet your specific needs.

For more information or to request personalized support, please reach out to us at info@3d-labs.com or call us at 0091- 7780374207.

Trust 3D-LABS for accurate calculations and unwavering support throughout your project’s lifecycle.

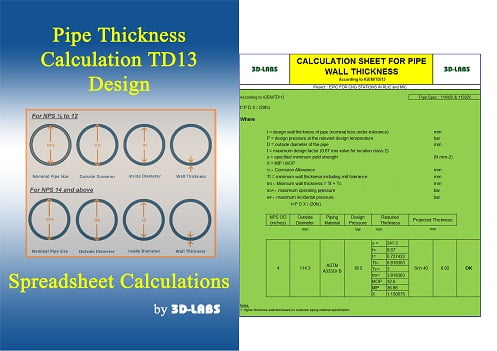

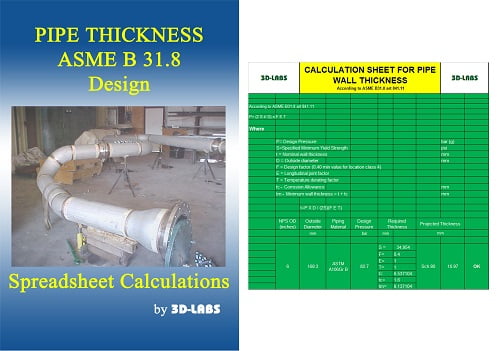

ASME TD13 is often used as the design standard for natural gas piping systems in several facilities, such as compressor stations, gas processing facilities, metering stations, storage tanks and gas transporting pipeline. The design pressure for steel gas piping systems or the nominal wall thickness for a given design pressure shall be determined.

This is the wall thickness computed using an applicable equation such as those stated in paragraph 841.1.1 of ASME B31.8 or any other applicable code. The nominal wall thickness computed may be used to order the pipe with or without allowance to compensate for under thickness.

Allowance is an additional thickness added to the pipe’s calculated wall thickness to cover up for any reduction in wall thickness that may result from manufacturing, handling, or corrosion.

Several allowances are considered in calculating pipeline wall thickness; they include, manufacturing allowance, mechanical allowance, and corrosion allowance.

The manufacturing allowance is mostly taken as zero because most of the pipes manufactured are error-free due to rigorous quality checks performed on pipes.

Corrosion allowance is a function of the fluid to be transported and its effect on the pipe material. Usually, pipes made of stainless steel, duplex stainless steel have a corrosion allowance of zero (0). The corrosion allowance is estimated by predicting the corrosion rate for the entire service years of the pipeline.

Reviews

There are no reviews yet.